WTEC Products are top of the line

WTEC does more testing than industry standards require. IEEE 386 requires either Impulse or AC Withstand. We run both on most of our products.

WTEC provides electrical components directly to turbine manufacturers and to wind farms in all phases of development. From the top of the tower to the utility interconnect; our product-packaged approach streamlines purchasing and material management while offering both cost and administrative savings.

WTEC has extensive knowledge of cable, tower internals, collection systems, substations and transmission lines, which allows our customers to take advantage of our expertise from the proposal stage to project completion. By offering cost and delivery evaluation, cross-referencing, material management and many other services WTEC ensures the cost-effective, on-time fulfillment of our customers' needs.

WTEC will find a solution for your project needs, whether that means a complete wind farm or a single component.

Low Voltage Cables & Cable Accessories

WTEC offers a wide range of cables and cable accessories for Wind Farms and Utility Scale Solar Projects. At the point of power generation to collection, WTEC supplies UL 4703 listed Photovoltaic Wire (PV), ranging from 600V to 2 kV applications, along with PV terminations/connectors and other associated accessories. From the point of collection to conversion, WTEC can provide various Low Voltage cable solutions, Aluminum and Copper, to meet any design criteria.

In addition to supplying materials, WTEC is a UL certified harness facility capable of manufacturing cable assemblies, to provide plug and play site installation.

Need a custom length? Give us a call at (201) 242-9906 or fill out our Professional Solar Services Inquiry Form!

Aluminum Conductor Cables

Size #8-1000 kcmil

600 V - 2 kV

AL 1350/8000 Series

ICEA S-95-658, LL49

UL Standard 854 for Type USE-2

UL Listed for RHH, RHW-2

THHN-THWN2, XHHW

Compression Lugs

Double Hole Connectors:

Long Barrel

Wire sizes 8 Gauge through 4/0 AWG

250 – 1000 MCM

Compression Connectors:

AL and CU

UL 486A

1-Hole, 2-Hole

Standard/Narrow Tongue

Multi Conductor Control Cables

Size 2/0 - 18 AWG

600 V or WTTC 1 kV

2 to 25 conductors or pairs

UL and CSA listed

Wet/ Dry Locations

Sunlight Resistant

Flame Retardant

DLO Copper Conductor Cables

600V - 2 kV

2/0 AWG – 929.2 kcmil

UL 1685

IEEE1202

CSA FT4

C22.2 No.38

NEC Article 310

RHH-RHW2

Cable Ties

Molded From a 6/6 Nylon

Variety of Sizes and Styles

Weather Resistant

For Outdoor Use

UL Standard 62275

UL 1565

NEC Section 300.22

UL Listed 181 B-C

Nuts, bolts and washers

Assorted Low Voltage hardware: Nuts, Bolts, Washers

Cable Harness

IPC-620-A Certified

ISO Certified 9001:2008

UL-817 – E#: E-319420

UL-508-A

UL-2277

UL-1741

Photovoltaic (PV) Wire

PV Wires

Size #8 - #14 AWG

600 V - 2 kV

UL 44

UL 4703

UL 1581

UL 854

Photovoltaic (PV) Wire Connectors

Size #8 - #14 AWG

600 V - 1 kV

H4 Connectors (Male/Female)

NEC 2008

IP67 standards

UL, TUV, IEC/CEI, NEC, & DIN V

WTEC Medium Voltage and Fiber Optic Cables and Accessories

WTEC does more testing than industry standards require. IEEE 386 requires either Impulse or AC Withstand. We run both on all of our products.

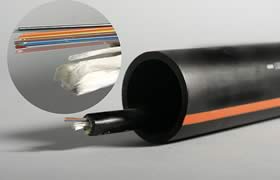

After power is converted into AC by the inverter and stepped by the transformer, electricity is then distributed throughout the collection system. The primary distribution mechanism would be via Medium Voltage Cables (15kV-35kV). WTEC MV Cables are sized from 1/0AWG thru 1500kcmil, and are offered in various types of construction and configuration. All cables are suitable for direct burial application, and can also be manufactured for Cable Tray installation. Also installed with the Medium Voltage Cables are underground fiber optic cables, which provide data communication between the power generators. WTEC also supplies MV cable accessories, such as termination & splice kits, which connect the cables to power equipment.

Aluminum and Copper Conductor Cables

15 kV – 35 kV

TRXLPE and EPR Insulation (100% and 133%)

Copper Concentric Neutrals or Copper Tape Shield

LLDPE/PVC/XLP Jacket

Deadbreak/Loadbreak Terminations

15 kV – 35 kV

200 A and 600/900 A

Aluminium and Copper

ANSI/IEEE Std 386:

For Separable Insulated Connector Systems

ANSI C119.4: For Electric Connectors

IEEE Std 592: For Exposed Semiconducting Shields

Surge Arrestors

15 kV – 35 kV

200 A – 600 A

MCOV Rating (kVrms) – 22, 24, 27, 29, 38

IEEE C.62.11

IEEE 386

Splice Kits, and Substation/Riser Pole Termination Kits

1/0 AWG - 1250 kcmil

Junction Boxes

Ground Sleeves, pre-installed with 15kV-35kV Junctions

6-144 Strand Fiber Optic Strand

Single Mode or Multi Mode

Dry Buffer or Gel-filled

Loose Tube

Dielectric Central Strength Member

Glass Yarns and Polyethylene Jacket

Direct Installations in Duct

Outdoors, Indoors and Direct Burial

1"-2" Innerduct

Pre-installed or separate

HDPE

SDR11-13.5

Grounding Conductors and Accessories

WTEC provides a variety of grounding conductors suitable for uninsulated hook up, jumpers and grounds in electrical construction. Bare copper conductors are primarily used in both aerial and buried applications; WTEC also offers an equivalent, copper clad steel, which can provide a significant cost savings. Along with these grounding cables, WTEC can supply various grounding terminations and connectors.

Bare Copper Conductors

#12AWG – 1000kcmil

Solid and stranded

Classes AA, A, B and C

Meets ASTM specifications:

B-1, B-2, B-3, B-787 and B-8

Hard, medium-hard and soft tempers

Copper Clad Steel Conductor

A Variety of Gauges

Single and Stranded

Available in 30% and 40% Dead-soft Annealed

Meets ASTM Specifications:

B-193, B-452, B-227, B-228 and B-910

Rural Utilities Service Listed

Grounding Accessories

Copper Grounding Lugs

Compression Connectors

Clips

Ground Straps

Ground Rods and Exothermic and Mechanical Connectors

WTEC Power Equipment Supplies

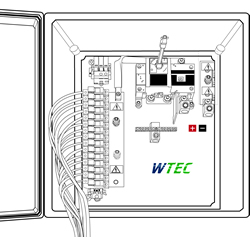

WTEC also provides three phase pad mount distribution transformers that are designed and manufactured to meet all applicable ANSI and RUS standards for installation on three phase underground systems. These transformers step up the output voltages of the inverters to the required distribution voltage. Available ratings are 30 kVA – 3.0 MVA with high voltages 2.4 – 34.5 kV (150 kV BIL) and low voltages up to 600 V. WTEC is a UL508A panel facility (E317121) that has been providing panels, such as combiner boxes, to the renewable energy industry for over a decade. We are able to provide combiner boxes with multiple string configurations, listed to UL1741 standards, and enclosures that are NEMA 4X Fiberglass, and NEMA 3R, 4, 4X stainless steel.

Combiner Boxes

600 V-1000 V

NEMA 4X Fiberglass Enclosure

Up to 24 Inputs

Available Current Monitoring

Rated up to 50 Degrees Celsius

UL1741 Certified

GSU Padmount Transformers

12.47kV – 35kV

3-Phase Liquid-Filled

Integrated Breakers Available

Grounding Transformers

34,500/480V

Grounded Wye/Delta

Conforms with ANSI C57.12.00, C57.12.26, C57.12.90, C57.12.28, ANSI/IEEE 32-1972

Switchgear

12.47 – 35kV

Utilize SF6 Gas

SEL-751A Feeder Protection Relays Available

Current Transformer For Control Use

Complies with IEEE C37.72, C37.34, C37.60, ANSI/IEEE 386, IEC 60265-1

12 Gauge Galvanized Steel Enclosure

Breakers

Up to 2500 Amps

Available with 2 or 3 Poles

WTEC Overhead/Transmission Line Cables

After all power is collected from the solar arrays, they are transmitted to the electrical substation, which steps up the voltage for connection to the main electrical grid. Overhead/Transmission Line cables are primarily used to distribute this power. ACSR cable offers optimal strength for transmission line design, and enables desired strength to be achieved without degradation of ampacity.

ASCR Conductor Cables

Aluminum Conductor Steel Reinforced

T-2

Optical Ground Wire (OPGW)

Stainless Steel Tube

Aluminium Core

Fibers Protected From Environmental Conditions

EHS Steel Wire

Strand Diameter 1/4" - 1"

Galvanized Steel Strand

Meets REA and ASTM Specifications:

A111, A363, A474, A475, A586, B500

Substation and Transmission

For more information please use our Contact Form to reach us.

WTEC provides substation and transmission material packaging using an organized purchasing and material management system. All equipment and materials are produced by top quality manufacturers.

Substation and transmission materials can be purchased by line item or in one convenient package. We are adaptable — meeting your desired scope of work.

Our process combines flexibility with conformance. Whether using your bill of materials or our material takeoff, WTEC staff makes sure that all items fulfill customer specifications.

We're committed to meeting your delivery requirements, working diligently with you to meet those critical deadlines.

In addition to materials, WTEC's Engineering Division offers substation design services.

Substation Materials

Products can be purchased as a package or as individual elements.

|

|

|

Transmission Line Products

Products can be purchase as a package or as individual elements

OVERHEAD CABLES

TRANSMISSION POLES

|

INSULATORS

HARDWARE

|

ANCHORS

GROUNDING

|

Steel Products and Services

All of our products adhere to all applicable industry standards, such as ASTM A570 and/or ASTM A992, and ASTM 123. Furthermore, utilizing our in-house engineers allows us to seamlessly integrate information from initial design through the final CNC shop-cutting programs.

Read the WTEC Steel Products Brochure for more information.

I-Beams and C-Channels

Fabricated to any specification. Includes W6x7, W6x8.5, W6x9, W6x12, W6x15

Tubular and Square Pipes

Fabricated to any specification. Diameters from: 1/8" - 10". Wall Thickness: Schedule 20, 40, 80, or higher

Circular and square HSS have very efficient shapes for multiple-axis loading as they have uniform geometric and thus uniform strength characteristics along two or more cross-sectional axes; this makes them good choices for columns. They also have excellent resistance to torsion.

Helical Piers

Fabricated to any specification

Helical piers, also referred to as helical piles, screw piles, steel screw-in foundations, screw piers or screw anchors, are a steel screw-in piling and ground anchoring system used for building foundations. Screwpiles are manufactured using varying sizes of tubular hollow sections for the pile or anchors shaft.

OEM Products

WTEC delivers OEM electrical internals from the Nacelle to the Down Tower System. Our value-added services offers customers cost out opportunities leveraged from our purchasing volume and expert labor force. We serve not only manufacturers, but also repair and maintenance companies.

Our 70,000 square ft of assembly manufacturing and warehouse space houses a full inventory of cables, cable glands, light fixtures, lugs and ferrules. This immense stock, along with our superior packaging operation, provides customers with the guarantee of a cost-effective, efficient purchase. WTEC has recently added capabilities to manufacture molded cable assemblies for Solar and Wind industries.

Our customized electrical internals are designed, packaged and kitted for efficient installation.

For more information please use our Contact Form to reach us.

Marked and Bundled Photovoltaic (PV) Assembly

The WTEC Bundled Plug and Play Wire Harness is tray rated, and can be used in aerial and direct burial applications. The harness is made of the highest quality components, and is designated to considerably decrease the time required to install the harness while significantly increasing the number of harnesses that can be installed daily.

The WTEC Bundled Plug and Play Wire Harness is tray rated, and can be used in aerial and direct burial applications. The harness is made of the highest quality components, and is designated to considerably decrease the time required to install the harness while significantly increasing the number of harnesses that can be installed daily.

The WTEC PV Bundled Plug and Play Wire Harness is produced in a controlled UL Harness and Panel shop. The harness can be produced in multiple conductor sizes and counts, multiple lengths, breakouts, and prewired in a combiner box allowing for units to be delivered to the job site installation ready.

Engineering

The WTEC Engineering Division resolves customer problems by developing effective, cost-efficient solutions. Our seasoned engineers have years of cable design and application expertise.

Our team works with you to provide cost out opportunities, including cable sizing and applications, as well as code compliance. It also provides engineering guidance for the makeup of cables and harnesses to customer specifications.

WTEC provides design and analysis from generator to grid, including tower internals, collections systems and substations.

For more information please use our Contact Form to reach us.

Cable Installation

In order to compliment its affiliated companies, WTEC has formed AED to provide installation services for wind farm collection systems. AED utilizes a noninvasive trenching method that minimizes ground surface damage and provides a high speed, cost efficient solution to your trenching needs. The company's single pass installation method permits the laying of the URD cable, fiber, ground conductor and marking tape, followed by backfilling and compaction in one motion.

AED's fleet of Rivard trenchers are extremely versatile, operating in both loose rock and soil. The company has expanded its installation flee with Tesmec rocksaw trenchers that can cut through hard rock at up to 32,000 psi. AED's technicians and equipment operators are highly trained industry professionals, experienced in trenching and laying cables.

For more information visit www.AED.US.com

Balance of System Products

WTEC delivers total electrical system solutions to BOP contractors, owners, developers and EPC companies.

We have all the quality materials needed for a successful project — starting with the Wind Turbine Generators (WTG) low voltage distribution panel, padmount transformer, collection system to the home run feeders and ending at the substation.

WTEC designs and delivers cable to customer collection system specifications — whether overhead, underground or both.

For more information please use our Contact Form to reach us.

Turchi Post Driver

Track drive diesel powered hydraulic post driver for solar farm applications

When WTEC shows up to do an installation you know it will be done safely, quickly, and precisely. A large part of that formula is the use of the state of the art Turchi Post Driver.

We can help you install piers/beams using the Turchi machine or you can buy the machine from us.

WTEC's Turchi Machines Offer:

WTEC's Turchi Machines Offer:

- Less Man-Power for Operation

- Installation Time Reduction. 200 or more Posts per Day!

- Cost-Effective

- Compatible With Many Beams and Piers

- Higher Precision During Installation

Read more about Turchi at www.turchi.com.au